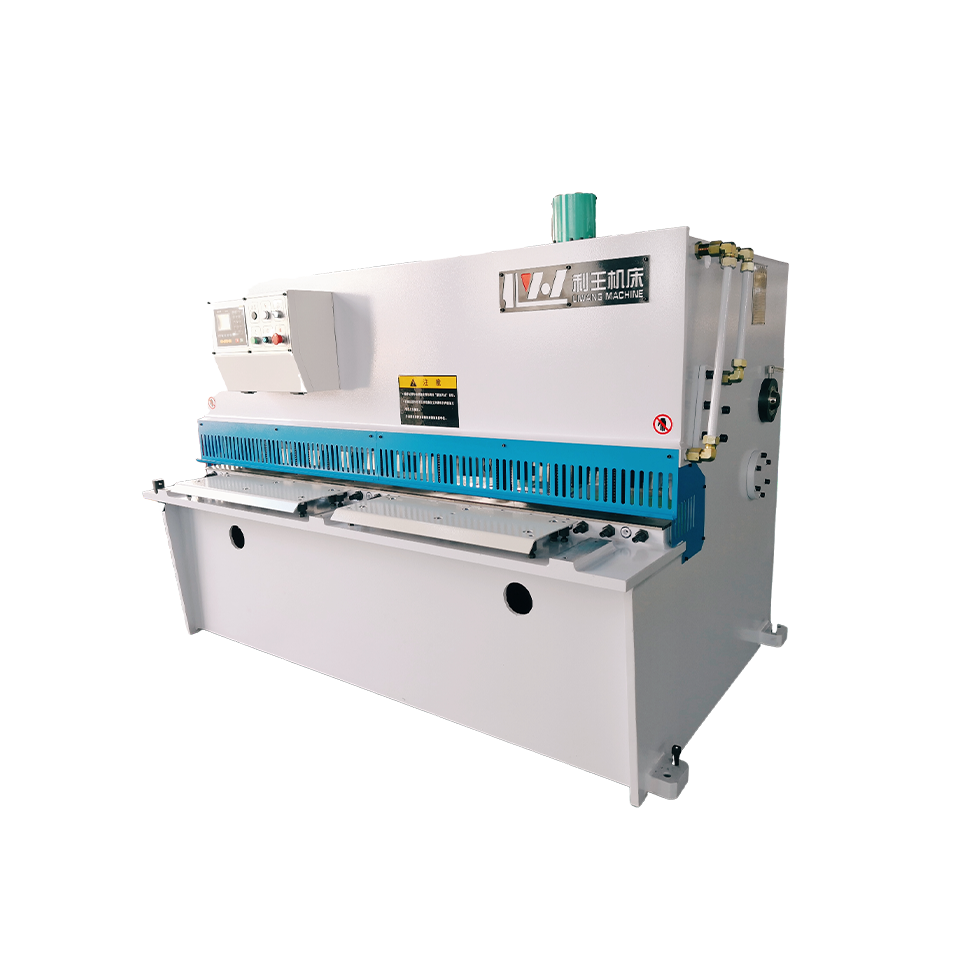

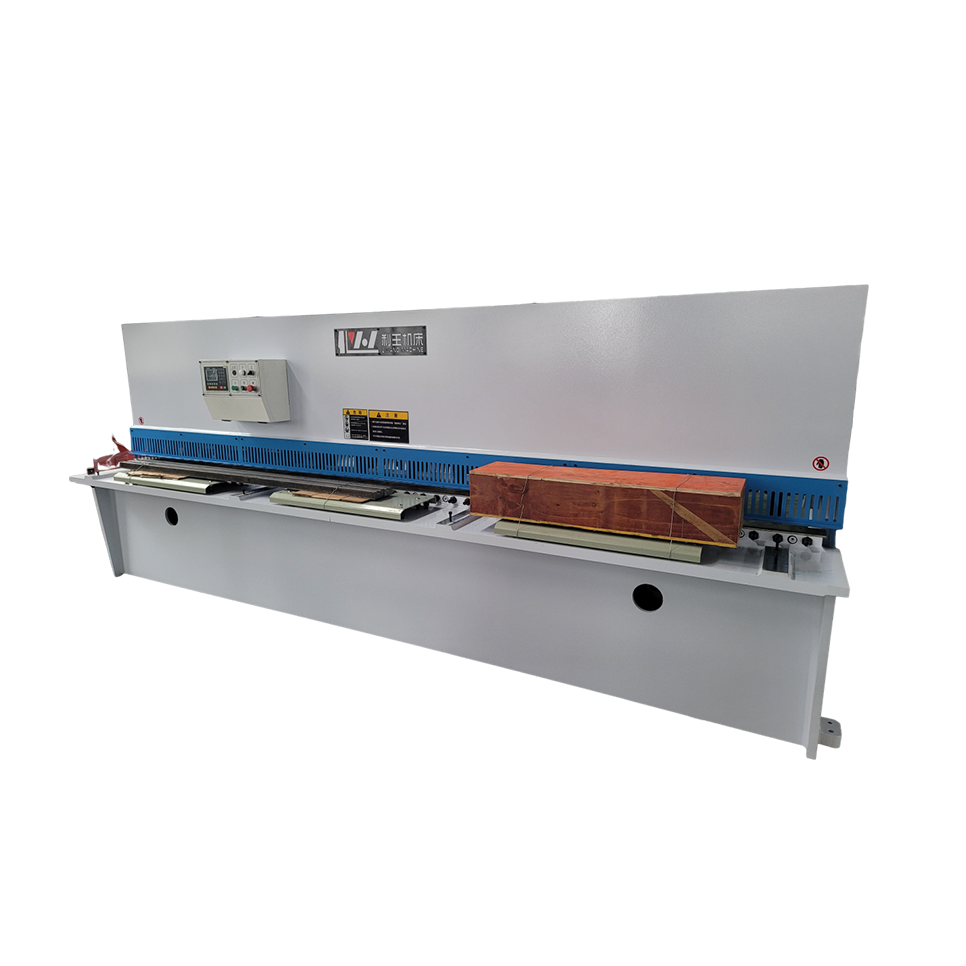

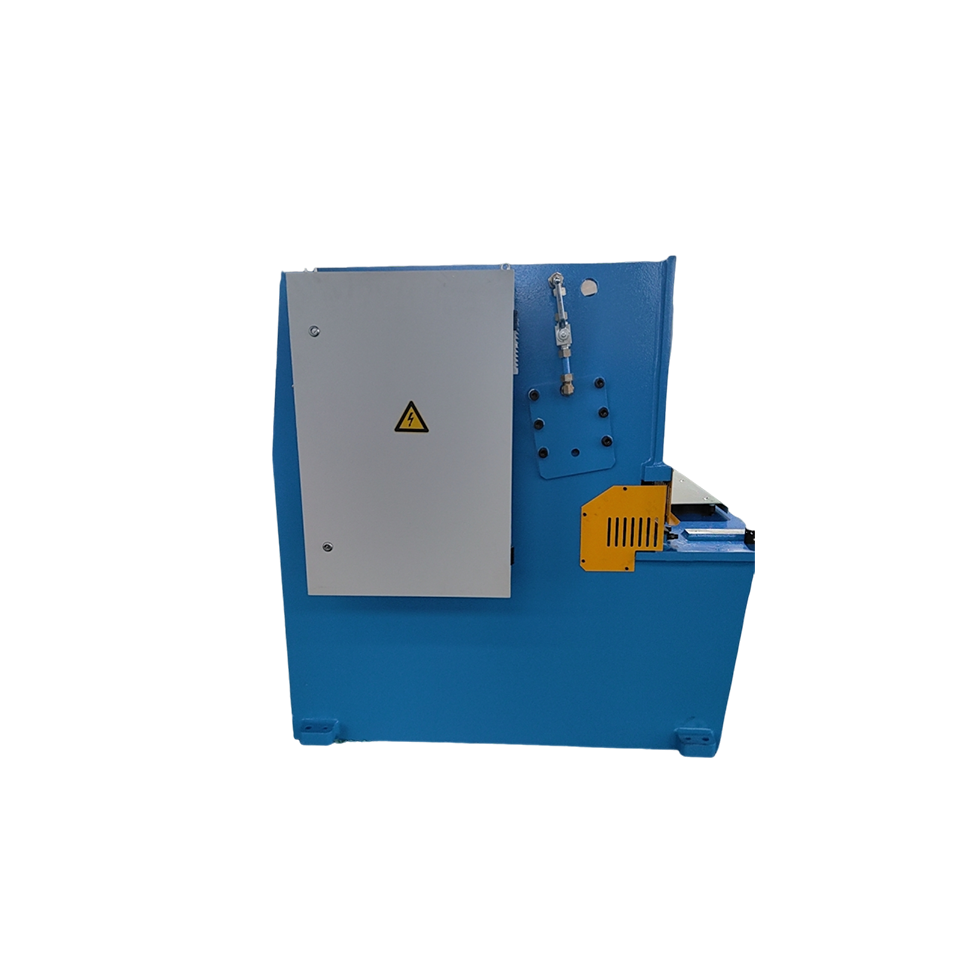

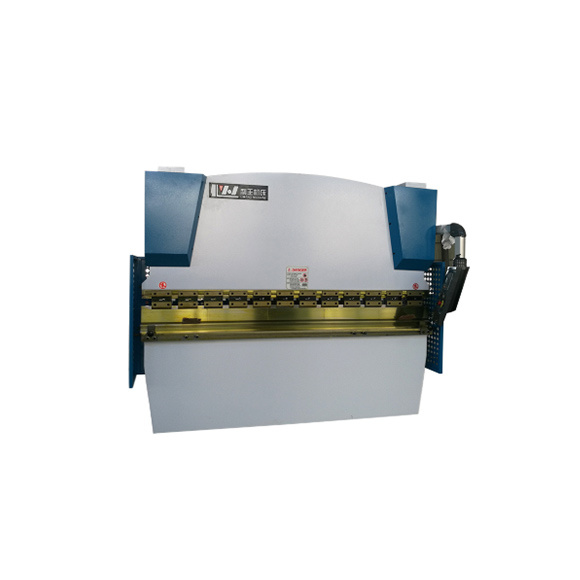

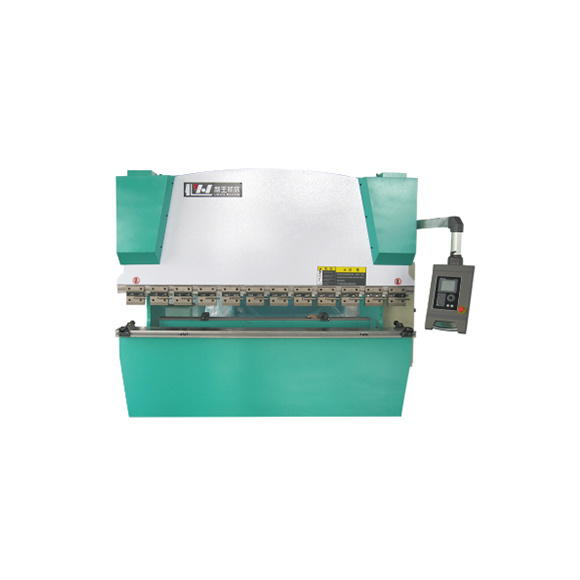

Bending Machine

Category:

Nantong Liwang Shearing and Bending Machine Tool Co., Ltd. is one of the key enterprises in the national machinery industry producing shearing and bending machine tools. It mainly produces the "Liwang" brand series of bending machines, shearing machines, plate rolling machines, and decoiling leveling shearing production lines.

Liwang

Keywords: Hydraulic Press | Corner Cutting Machine | Shearing Machine | Bending Machine

Tel:

Product Description

Nantong Liwang Shearing and Bending Machine Tool Co., Ltd. is one of the key enterprises in the national machinery industry producing shearing and bending machine tools. It mainly produces the "Liwang" brand series of bending machines, shearing machines, plate rolling machines, and decoiling leveling shearing production lines.

The products are specially designed to provide the required specialized machinery and complete sets of equipment for industries such as aviation, light industry, shipbuilding, metallurgy, chemical, construction, automotive, electronics, electric power, and decoration. The products are sold nationwide and to Southeast Asia, as well as exported to Europe and America.

1. Machine Model and Name

1.1 Model: WC67Y Series Digital Display Hydraulic Press Brake

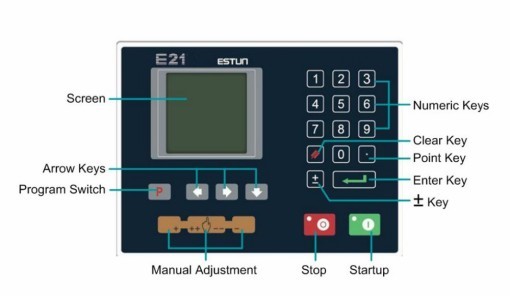

1.2 CNC System: E21

2. Product Standards:

JB/T2257.1 "Sheet Metal Press Brake Technical Conditions"

GB/T14349 "Sheet Metal Press Brake Accuracy"

JB/T54363 "Sheet Metal Press Brake Quality Product Classification"

3. Overall Machine Performance

3.1 Structural parts are welded steel plates with strong rigidity.

3.2 Structural parts are rust removed by grinding and coated with anti-rust paint.

3.3 The machine's columns, upper working slider, and lower workbench are processed using large floor boring and milling machines with one-time integral machining to ensure overall machining accuracy.

3.4 Upper moving bending design, stable operation, convenient and safe.

3.5 Pressure holding delay function at the bottom dead center to ensure workpiece accuracy.

3.6 Large slider stroke with high parallelism tolerance on both sides.

3.7 Under relevant national standards, bending angle accuracy can reach ±1°.

3.8 Equipped with slow descent control function, allowing operators better control of the workpiece.

3.9 Motor-driven back gauge with fast speed, smooth transmission, high precision, and low noise.

4. Hydraulic System

4.1 Uses Sino-US joint venture Shandong Taifeng press brake dedicated control system for high control accuracy. Hydraulic system has overload overflow protection, safe and reliable.

4.2 Oil pump selected is a high-pressure internal gear pump capable of withstanding high pressure with low noise.

4.3 Cylinder: 45# steel with tempering treatment, precision bored and ground inner hole.

4.4 Piston: 45# steel with tempering treatment, outer circle high-frequency quenching or chrome plating, precision grinding, vibration grinding (super finishing).

4.5 Seals selected from Japan NOK company, good sealing performance, reliable operation, and long service life.

4.6 Clear and intuitive oil level and temperature display.

5. Electrical Control System

5.1 Key electrical components use domestic Siemens, meeting international standards, safe and reliable, long service life, strong anti-interference ability.

5.2 Movable foot pedal switch operation.

6. CNC Axis Functions

6.1 Y-axis controls slider stroke, used to control bending angle.

6.2 X-axis controls back gauge, used to control flange size of the press brake.

X-axis is driven by motor through sprocket to move the screw. Two back gauge claws remain synchronized during movement. Transmission is smooth, high precision, and low noise.

7. Molds

One set of standard upper and lower molds

8. Machine's Anti-Eccentric Load Capability

This machine uses torsion shaft synchronization to keep the slider parallel to the workbench even under full eccentric load.

9. Digital Display System

E21 digital display system: digital display of back gauge and mechanical block positions.

10. Technical Parameters

| No. |

Name |

Picture |

Brand |

|

1. |

Main Motor |

|

Siemens (Sino-foreign joint venture) |

|

2. |

Main Electrical Components |

|

Siemens |

|

3. |

Back Gauge |

|

|

|

4. |

Hydraulic Valve |

|

Taifeng (Standard) Rexroth (Optional) |

|

5 |

Ball Screw

|

|

Yes |

|

6 |

Upper and Lower Molds |

|

|

|

7 |

Air Cooling |

|

Optional |

|

8 |

Safety Protection |

|

Optional |

| WC67Y Digital Display Press Brake | ||||||||||||

| Model | Nominal Force | Workbench Length | Distance Between Columns | Throat Depth | Cylinder Stroke | Max Opening Height | Slider Speed | Main Motor Power | Overall Dimensions | Machine Weight | ||

| Fast Down | Working Feed | Return | ||||||||||

| KN | mm | mm | mm | mm | mm | mm/s | mm/s | mm/s | KW | mm | kg | |

| WC67Y-40/2000 | 400 | 2000 | 1550 | 250 | 120 | 325 | 70 | 9.5 | 80 | 4 | 2150×1185×1950 | 2600 |

| WC67Y-40/2500 | 400 | 2500 | 2050 | 250 | 120 | 325 | 70 | 9.5 | 80 | 4 | 2650×1185×1950 | 3000 |

| WC67Y-63/2500 | 630 | 2500 | 2050 | 250 | 120 | 330 | 80 | 12 | 100 | 5.5 | 3450×1230×2180 | 4200 |

| WC67Y-63/3200 | 630 | 3200 | 2600 | 250 | 120 | 330 | 100 | 12 | 100 | 5.5 | 3350×1230×2220 | 5100 |

| WC67Y-80/2500 | 800 | 2500 | 2050 | 320 | 120 | 370 | 80 | 10.5 | 80 | 7.5 | 2650×1325×2290 | 5800 |

| WC67Y-80/3200 | 800 | 3200 | 2600 | 320 | 120 | 370 | 80 | 10.5 | 80 | 7.5 | 3350×1325×2350 | 6100 |

| WC67Y-100/2500 | 1000 | 2500 | 2050 | 320 | 120 | 380 | 80 | 10 | 70 | 7.5 | 3350×1350×2350 | 6000 |

| WC67Y-100/3200 | 1000 | 3200 | 2600 | 320 | 120 | 380 | 80 | 10 | 70 | 7.5 | 3350×1350×2420 | 6600 |

| WC67Y-100/4000 | 1000 | 4000 | 3200 | 320 | 120 | 380 | 100 | 10 | 70 | 7.5 | 4150×1390×2510 | 8100 |

| WC67Y-125/3200 | 1000 | 3200 | 2600 | 320 | 120 | 380 | 100 | 10 | 70 | 7.5 | 3350×1350×2420 | 7000 |

| WC67Y-125/4000 | 1000 | 4000 | 3200 | 320 | 120 | 380 | 100 | 10 | 70 | 7.5 | 4150×1390×2510 | 8500 |

| WC67Y-160/3200 | 1600 | 3200 | 2600 | 320 | 180 | 450 | 100 | 8 | 80 | 11 | 3350×1590×2560 | 9500 |

| WC67Y-160/4000 | 1600 | 4000 | 3200 | 320 | 180 | 450 | 100 | 8 | 80 | 11 | 4150×1590×2560 | 11200 |

| WC67Y-200/3200 | 2000 | 3200 | 2600 | 320 | 200 | 470 | 90 | 8 | 100 | 15 | 3370×1740×2870 | 12700 |

| WC67Y-200/4000 | 2000 | 4000 | 3200 | 320 | 200 | 470 | 90 | 8 | 100 | 15 | 4170×1750×2920 | 15300 |

| WC67Y-250/3200 | 2500 | 3200 | 2600 | 400 | 250 | 530 | 70 | 8 | 50 | 18.5 | 3440×1840×3040 | 15700 |

| WC67Y-250/4000 | 2500 | 4000 | 3200 | 400 | 250 | 530 | 70 | 8 | 50 | 18.5 | 4240×1900×3110 | 18500 |

| WC67Y-300/3200 | 3000 | 3200 | 2600 | 400 | 250 | 560 | 60 | 9 | 65 | 22 | 3300×2060×3120 | 19400 |

| WC67Y-300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 560 | 60 | 9 | 65 | 22 | 4210×2135×3320 | 21700 |

| WC67Y-300/6000 | 3000 | 6000 | 4700 | 400 | 250 | 560 | 60 | 9 | 65 | 22 | 6050×2250×4205 | 29600 |

| WC67Y-400/4000 | 4000 | 4000 | 3100 | 400 | 300 | 640 | 60 | 8 | 60 | 30 | 4210×2280×3870 | 30000 |

| WC67Y-400/6000 | 4000 | 6000 | 4700 | 400 | 300 | 640 | 60 | 8 | 60 | 30 | 6050×2335×4635 | 34500 |

| WC67Y-500/4000 | 5000 | 4000 | 3100 | 500 | 300 | 640 | 70 | 8 | 70 | 37 | 4050×2445×4320 | 31800 |

| WC67Y-500/6000 | 5000 | 6000 | 4700 | 500 | 300 | 640 | 70 | 8 | 70 | 37 | 6050×2445×4690 | 43200 |

| WC67Y-600/6000 | 6000 | 6000 | 4700 | 500 | 300 | 650 | 70 | 8 | 70 | 45 | 6050×2680×5700 | 53500 |

Related Products

Welcome to leave your inquiry